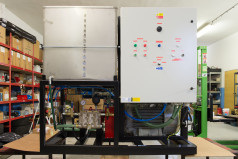

Hydraulic Descaling System

Scale is a layer of oxide developed on the surface of the steel because of high temperatures, up to 1250 °C, and the presence of oxygen and different gases. High pressure water descaling is used as an effective method for removing scale from the surface of a hot metal semi-finished product with a high pressure water jet. This improves the surface quality of the final product.

Hydraulic descaling is most often used before and during hot metal forming. Scale is formed during the heating of semi-finished products in the furnace and during the subsequent thermoforming process. It is necessary to remove the scale so that they are not pushed into the base material during forming (forging, rolling) and thus the mechanical properties and quality of the semi-finished products are not reduced.

If a layer of scale is not removed from the surface of the material during the rolling or forging process, the subsequent metal forming will cause economic losses to the producers not only due to reduced production quality but also increased rolling mill and forging press maintenance costs due to rapid wear.

Parameters of high pressure descaling system

- flow rate: 50 – 500 l/min

- pressure: 150 – 300 bar

- electric motor power: 15 – 315 kW